Description

Our technical requirements for three way angle valves: The electroplating surface has a uniform luster and cannot be peeled, cracked, scorched, exposed at the end, peeled off, and has obvious pitting, burr and other defects.

Product Details

Our technical requirements for angle valves:

The electroplating surface has a uniform luster and cannot be peeled, cracked, scorched, exposed at the end, peeled off, and has obvious pitting, burr and other defects. The polished surface is smooth, there is no obvious burr, scratches and other phenomena.

There are no obvious defects such as trachoma, shrinkage holes, cracks, and pores on the casting surface.

There are no flashes, sink marks, warpage, weld marks, etc. on the surface of plastic parts.

There are no dents, broken teeth and other defects on the thread surface.

The product installation pipe thread shall meet the requirements of the corresponding thread gauges: pass and stop, and the external thread shall meet Class B accuracy requirements.

There is no impurity such as copper shavings in the product cavity.

The handle and stem are firmly connected and do not loosen.

Turn the product switch light, smooth, no jamming, clockwise rotation is off, counterclockwise rotation is on.

The limit deviation of the angle between the two connecting threads of the valve body is not more than 20.

Angle valve installation tips:

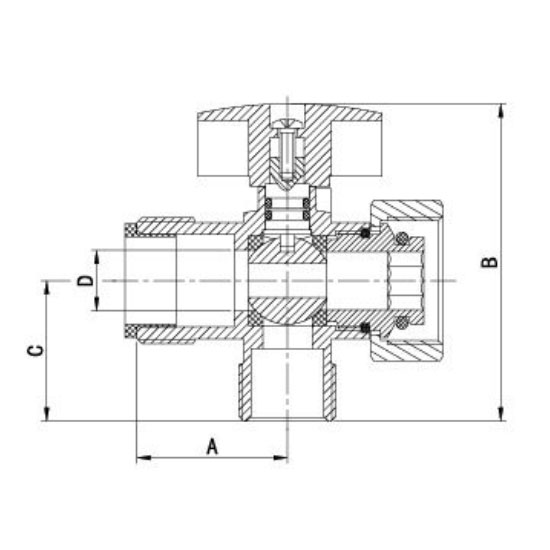

| DN | SIZE | A | B | C | D |

| 15 | 1/2"x3/4" | 31 | 65 | 28.5 | 12 |

| Pressure and temperature limitations for PN rated value | |||||

| PN | Pressure and temperature range | Pressure and Max temperature | |||

| ≤1.6Mpa | 16bar (-10℃ to 80℃) | 5bar (150℃) | |||

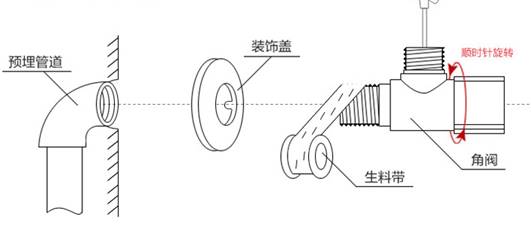

1. Before installation, it is necessary to drain water to flush sediment and other debris in the pipeline.

2. Insert the decorative cover into the inlet of the angle valve.

3. Wrap the raw material tape around the threaded end of the angle valve and manually screw it into the pre-embedded tube.

4. Insert the water outlet with a screwdriver and rotate clockwise until the angle valve is tightened to adjust the angle of the outlet of the angle valve.

5. Open the pipe valve and check that the threaded connection is sealed.

Raw material tape, hemp, and liquid raw material tape can be used for the sealing of threads. When used in large quantities, the economical type is better, and the raw material belt is more convenient for home use. The newer liquid raw material tape is actually an anaerobic adhesive, which is coated on the thread to prevent leakage. The disadvantage is that it takes a few hours to one day to test the water. The advantage is that it does not require tight tightening to achieve leakproofness. Effect.

The position of the thread seal must be wrapped around the raw material, and the place sealed by the rubber pad cannot be wrapped with the raw material tape. If it is wrapped around, it is easy to leak. This should be noted.

English

English Español

Español Русский

Русский Français

Français